Nano-Based Coatings

At Nanosentrix, we develop high-performance nano-based coatings engineered at the molecular level for superior protection and durability across diverse applications.

Featured services

Why Choose Nano coatings?

Nano-based coatings are built on cutting-edge nanotechnology to deliver performance far beyond traditional solutions. Here’s what sets us apart:

Nano-Level

Strength

Densely packed nanostructures create an ultra-durable barrier against wear, abrasion, and corrosion.

Tailored for

Versatility

Compatible with glass, metal, polymers, textiles, and more—ideal for industries like automotive, construction, electronics, and healthcare.

Extreme Environmental

Resistance

Shields surfaces from UV radiation, moisture, high heat, and harsh chemicals.

Long-Lasting

Performance

These coatings offer extended surface protection, maintaining their effectiveness and appearance even under harsh environmental and industrial conditions.

Transparency

Maintains clarity and appearance while providing invisible protection.

Versatile Across

Industries

From automotive and aerospace to construction and healthcare, Nanosentrix deliver customized solutions that exceed industry standards.

Nano Coating

Different types of Coatings

Anti–Corrosive Coating

Anti Scratch Coating

Fender Coating

High Temperature Coating

Self Cleaning Coating

Brush Coating

UV Blocking Coating

Heat Resistant Coating

Anti-corrosive coating is a graphene based and enhanced with a natural plant extract, offers superior protection against corrosion for all types of metal surfaces. Unlike conventional zinc-based coatings, this innovative formulation combines the strength of graphene with the natural properties of plant-based ingredients to provide unmatched corrosion resistance.

Field trials have demonstrated its exceptional performance in real-world conditions, making it a more reliable choice compared to traditional solutions. This coating creates a durable shield, protecting metal surfaces from moisture, salt, oxidation, and exposure to harsh chemicals.

The anti-scratch coating is specifically developed for glass surfaces, forming a durable, transparent protective layer that minimizes surface damage and enhances longevity. Leveraging nano-based technology, the coating significantly improves scratch resistance while maintaining the glass’s original clarity. This results in smoother, more resilient surfaces that are easier to clean and maintain—making it ideal for high-performance and demanding applications.

Fender coating is designed to keep automobile fenders free from dirt, mud, and road debris. This self-cleaning coating forms a hydrophobic barrier that allows contaminants to easily slide off, significantly reducing the need for frequent cleaning. The smooth surface created by the coating prevents the accumulation of dirt and mud, helping maintain the fender’s appearance and functionality for a longer time.

This coating has undergone rigorous field trials, delivered exceptional results in real-world conditions.

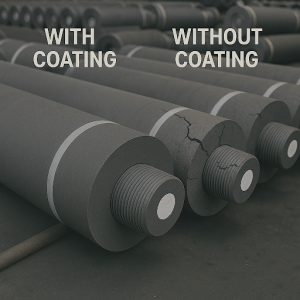

High-temperature coating is specifically designed for graphite electrodes used in the steel industry, particularly in electric arc furnaces. This specialized coating acts as a protective barrier, isolating the graphite electrodes from the harsh furnace environment. By preventing direct contact between the furnace gases and the graphite surface, the coating reduces exposure to oxygen and other oxidizing agents. This slows down the rate of oxidation, mitigates wear and tear, and significantly enhances the performance and longevity of the electrodes, enabling them to withstand temperatures up to 1800°C.

Self-cleaning coating enhances solar panel performance by creating a hydrophobic surface that repels dust, dirt, and water. This prevents the buildup of contaminants, keeping panels cleaner for longer and maximizing solar energy efficiency through improved light absorption. Designed for minimal maintenance, it lowers cleaning frequency and extends panel lifespan. The coating is also suitable for glass, automotive surfaces, and facades, keeping them cleaner and more durable in demanding environments.

Makeup brushes used with oil-based cosmetics often require extensive cleaning to remove residues that can support the growth of bacteria and fungi. Our nano-based Brush Coating offers an innovative solution by forming an ultra-thin layer on bristles that repels oils, water, and microbes. By preventing makeup residues from binding to the bristles, it simplifies cleaning, enhances hygiene, and extends brush lifespan without altering brush performance or feel.

Prolonged exposure to ultraviolet (UV) rays can cause fading, discoloration, and reduced durability of materials. UV Blocking Coating is specifically engineered to protect surfaces from these harmful effects, preserving both appearance and functionality. This advanced coating is ideal for products in industries where exposure to sunlight is frequent, such as automotive, construction, and outdoor furniture. This coating extends the lifespan of products by shielding surfaces from degradation, helping them remain reliable, durable, and intact over time.

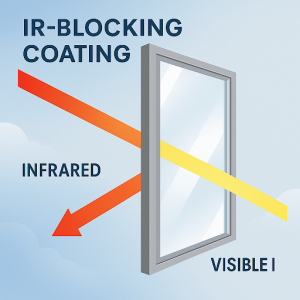

Heat-resistant coating is specifically designed to minimize heat transfer from sunlight—particularly infrared (IR) radiation—through glass. It effectively blocks IR and UV rays without compromising transparency, making it ideal for applications where both heat control and visibility are essential. Originally developed for glass, it also adheres well to various other substrates, offering broad utility in both architectural and automotive environments. By reducing IR transmission, it helps maintain interior comfort, lowers energy consumption, and prevents material degradation caused by UV exposure.