Conductive Inks & Printed Sensors

Conductive inks are specially formulated inks that contain conductive materials such as metallic particles, carbon-based nanomaterials. These inks can transmit electrical signals when printed onto substrates, enabling the creation of flexible, lightweight, and low-cost electronic circuits using conventional printing techniques such as screen printing, inkjet printing, gravure, and flexography.

Why Choose Conductive Inks & Printed Sensors?

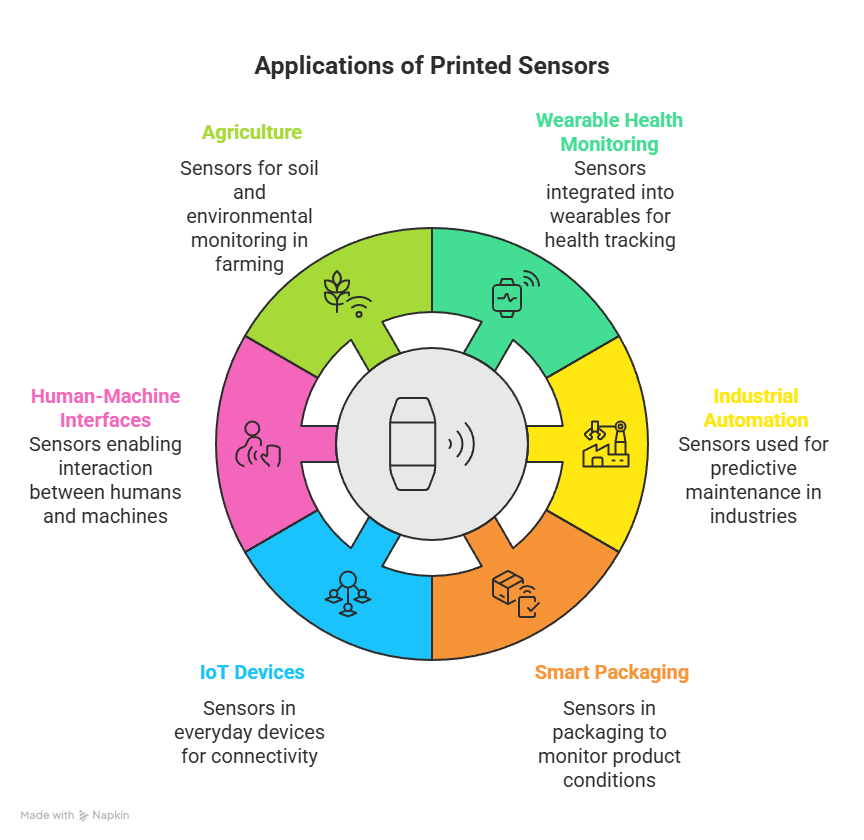

Unlike traditional copper wire-based electronics, conductive inks allow electronics to be printed on flexible substrates like plastics, paper, or textiles, making them ideal for wearables, sensors, RFIDs, printed batteries, flexible displays, and more.

Application

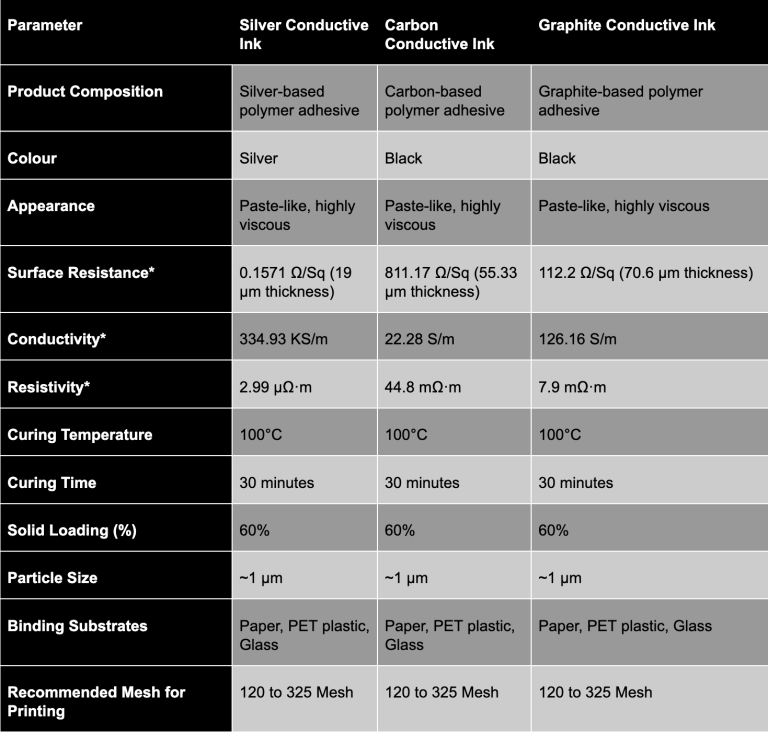

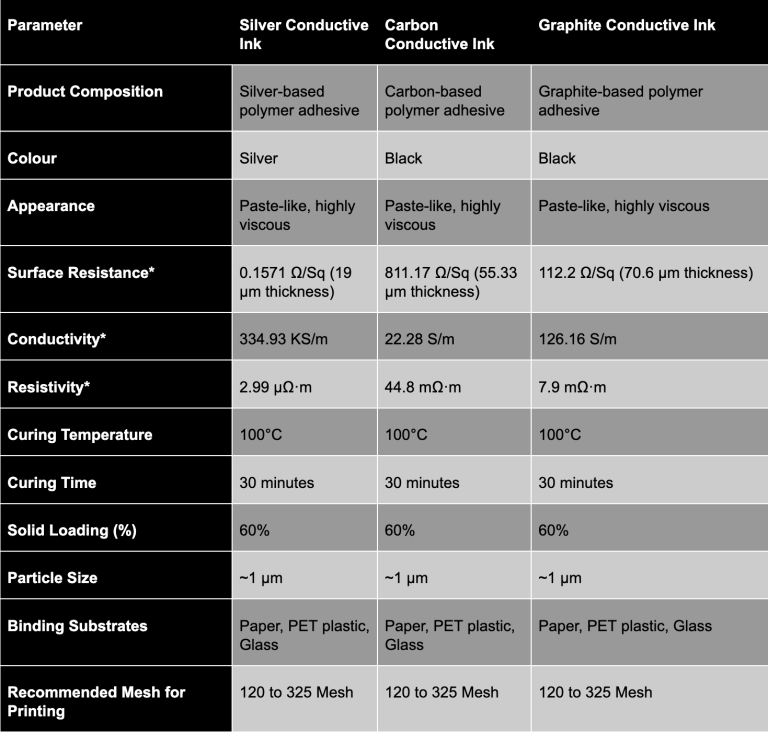

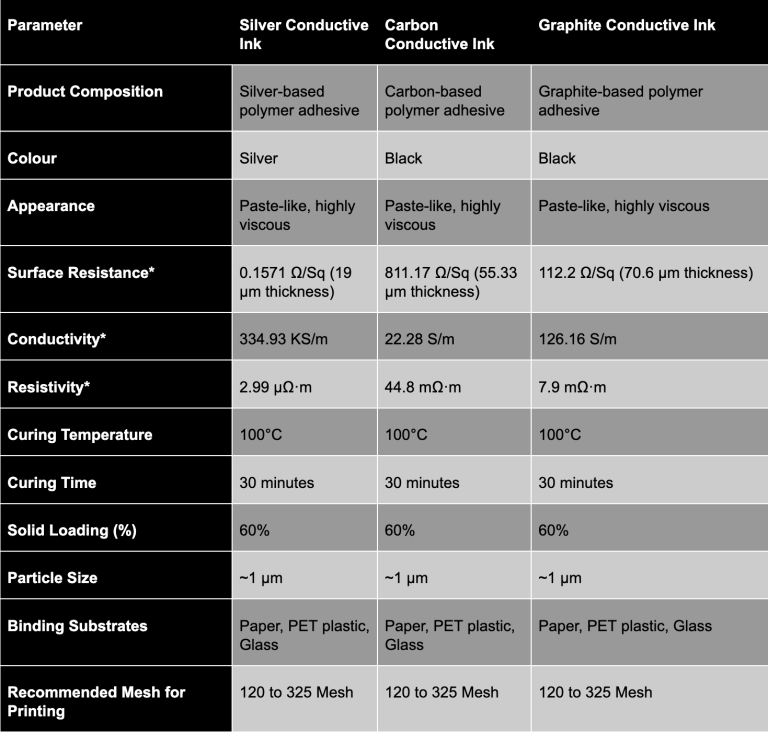

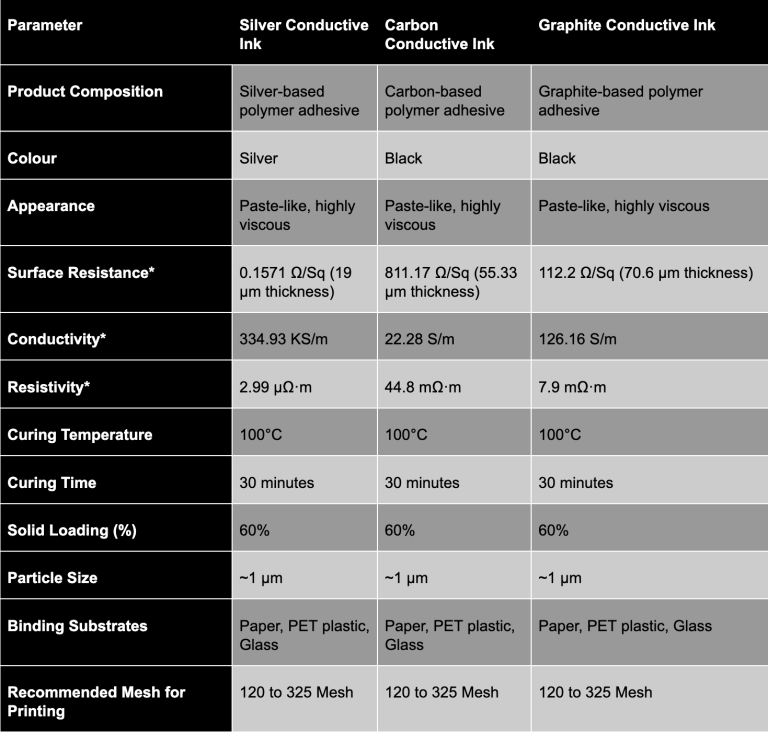

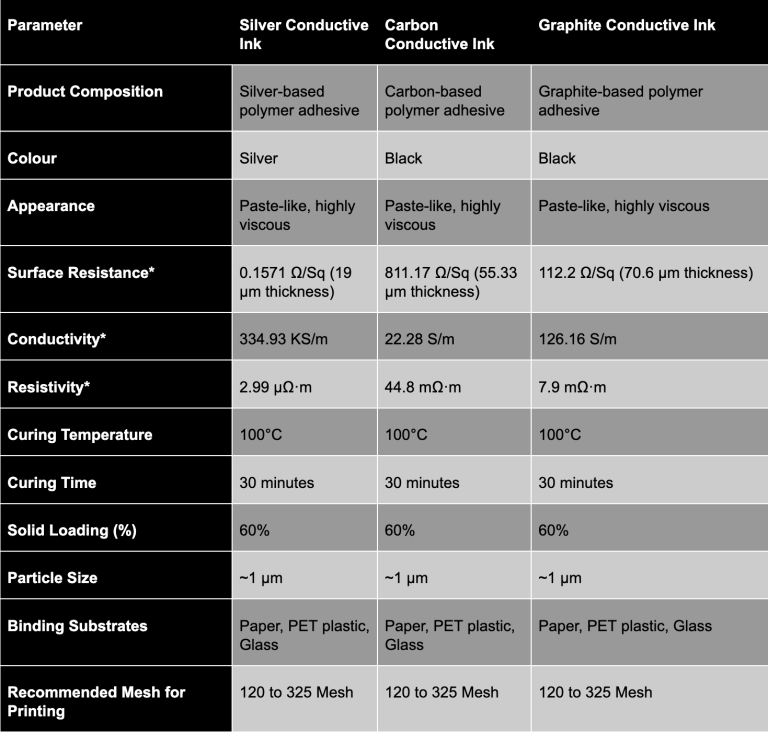

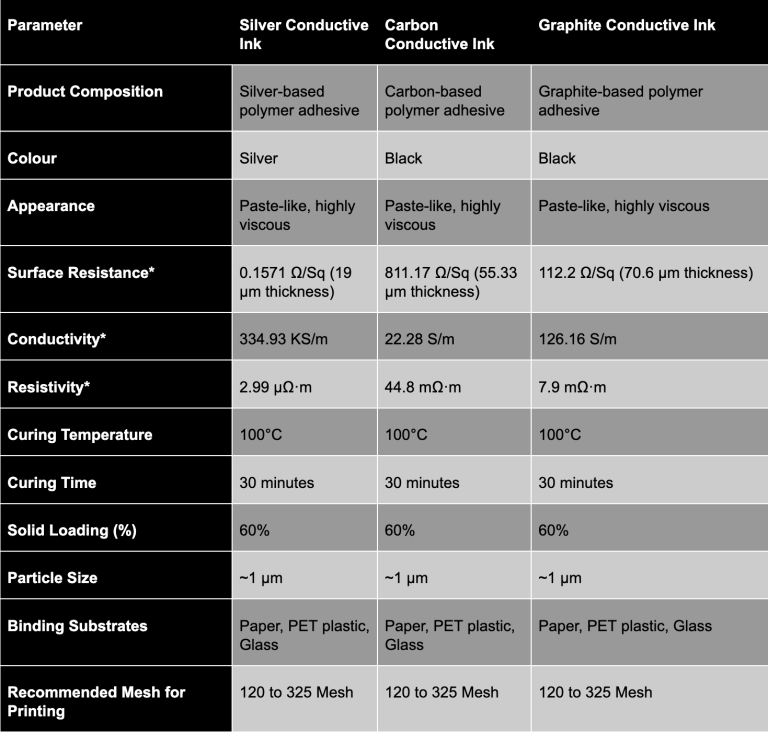

Different type of Inks

Silver conductive ink uses nano or micro-scale silver particles dispersed in a polymer matrix.

Composed of copper particles, often passivated or coated to reduce oxidation.

Consists of carbon black or amorphous carbon in a polymer binder.

Natural or synthetic graphite flakes dispersed in a binder system.

Ink made from reduced graphene oxide (rGO) or few-layer graphene.

Conductive ink using dispersed MWCNTs (concentric tubes of graphene).

Conductive ink using ultra-fine SWCNTs with high aspect ratios.

Usage Notes

- Mix well before usage.

- Always close the lid after usage.

- Recommended for screen printing applications.

- Customized formulations available on request.

Printed Sensors

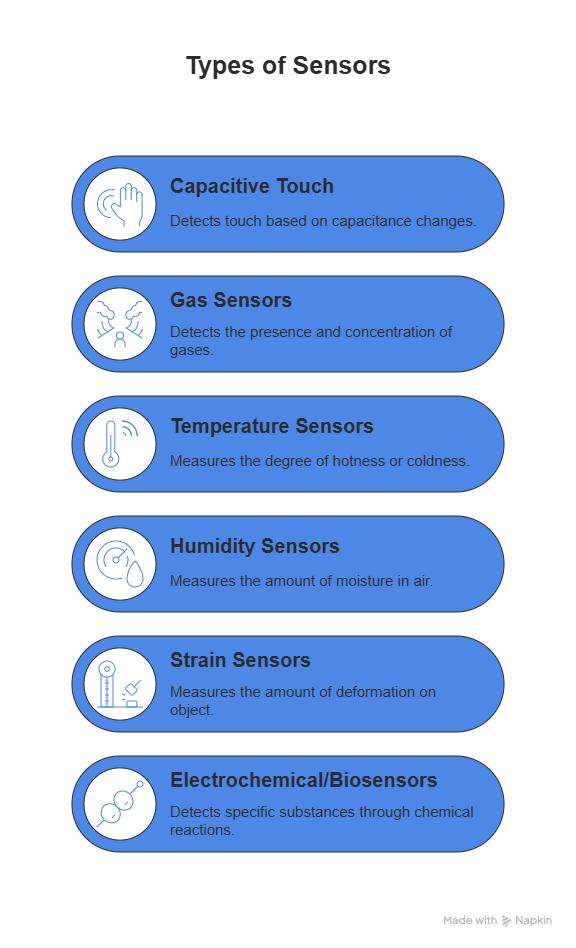

Printed sensors are thin, lightweight, and flexible devices fabricated using additive manufacturing processes such as screen printing. These sensors detect physical, chemical, or biological parameters such as pressure, temperature, humidity, strain, gas concentration, or biosignals.

By leveraging in-house developed conductive inks including silver, carbon, graphene, and carbon nanotubes, customized printed sensors are manufactured to match specific electrical, mechanical, and environmental requirements.

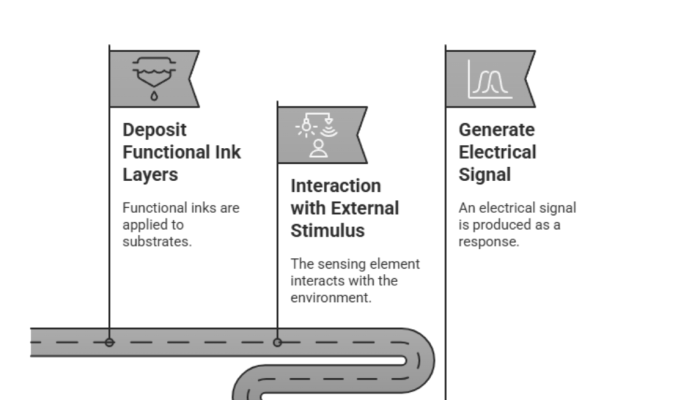

How Printed Sensors Work

Sensors are fabricated by depositing functional ink layers (e.g., electrodes, active sensing films, dielectric barriers) on substrates like PET, paper, polyamide, or textiles. The interaction between the sensing element and the external stimulus generates a measurable electrical signal.